Exothermic Welding Offers Better Electrical Joints Complying IEEE 837

The main purpose of the earthing system is to provide a path for fault currents to flow and dissipate into the ground which work as safety measure to protect human life as well as equipment. The joint and connection plays an important role in an effective earthing system. The JAM WELD Exothermic welding kit provides a definite molecular bonding among two or more metallic conductors to join them permanently having same or different cross-sectional area. This can be held by the process of exothermic reaction. The difficulties that have been encountered in conventional method of welding and jointing are: - jointing failure due to less contact surface area and aging due to atmospheric corrosion.

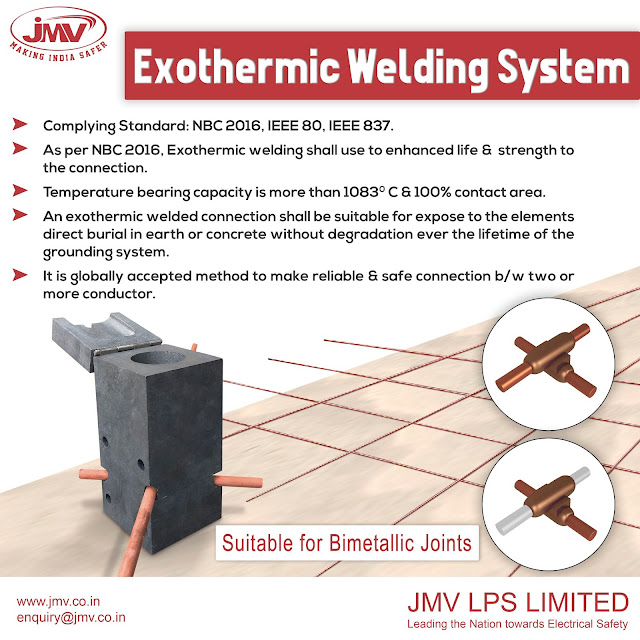

These problems are removed when exothermic solution comes in practice. It requires no external heat or force in its procedure. Unlike mechanical joints, the connection provides 100% contact surface area. This jointing can be made in between copper to copper, copper to steel etc. The exothermic welding solution is very reliable to offer better electrical performance. The components that take part into the process are:- Mold, Welding powder, handle clamp, Flint Gun, Cable Brush, scraper, brush, File card brush.

Exothermic Connection Process

Design a mold cavity which is completely depending upon the kind of joint and on the sizing of conductors which needs to be welded. The mold is made up of good quality graphite which can make 80 connections at a time. The JAM WELD is flammable yet non- hazardous, used to make the connections. A light-weighted clamp is used to safely position the weld inside the mold. After placing the conductor into the cavity, put the metallic disk at the bottom of it properly. Pour the JAM WELD into the mold crater. Also pour the starting powder over weld crumb to burn the reaction and then close the lid. Ignite it for 2-3 minutes by using a flint igniter. When the material get solidifies, open the mold and remove the slag by using a tool.

The weld powder is available in 25 gm, 40 gm, 60 gm, 90 gm etc. Exothermic welding kit offers irreversible molecular bond along with higher conductivity. The life of joints is greater than the conductors involved in the process. It has high temperature bearing capacity and corrosion resistant property.

Very well written, thanks for sharing. Also visit Axis Electrical Components for Exothermic welding

ReplyDeleteThese Welding cables information is very useful thank for this article.

ReplyDelete