Permanent Joints With Exothermic Welding Kit

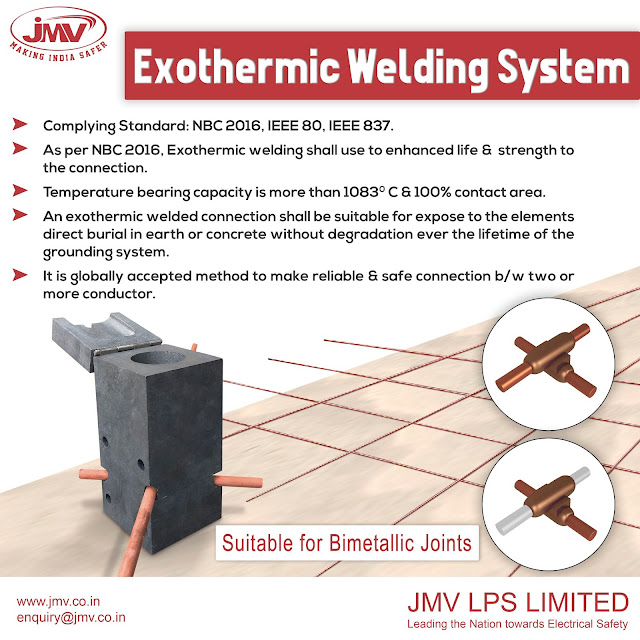

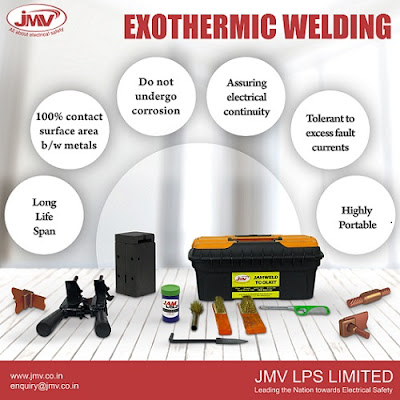

The guaranteed results when it comes to jointing is always labeled as the exothermic weld joints. Jointing is required in various shapes as per the concern. To build such strong connection joints, JAMWELD toolkit creates a vital role. The incorporation of the desire joints is accessible with the help of exothermic welding kit. The kit contains the abundant components that provide stable solution for endless jointing. 1. Exothermic Welding powder In the welding powder, the mixture of the metal oxide and copper compound both builds a sturdy joint that create an abiding connection. 2. Exothermic Welding Mould The mould is constructed with a graphite mould that oversee the molten weld flow and form an exothermic weld joint. 3. Exothermic Welding Handle Clamps In the exothermic welding, the handle clamp is a safe initiate that should be used properly du...