Referring to the permanent jointing technique known so far!

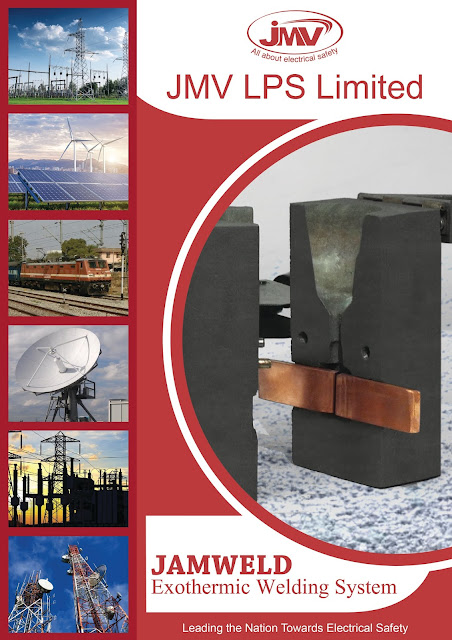

The advanced earthing system employs exothermic welding connections to make joints. This technique leads to the formation permanent molecular link for conductors. This simple and efficient methodology is compatible with copper, steel, brass, gunmetal, cast iron, etc. Earlier, we used bolting, brazing, crimping - which were some of the jointing techniques known to the people. These traditional methods make highly porous bonds which leads to faster corrosion. Hence there came the need for technological advancement.

What is exothermic welding process?

This is an important stage in earthing installation which is used to join two conductors and to make electrical connections. It is a crucial process which determines the continues flow of current which does not require any external heating provision. This is done to link bar to bar, bar to cable, cable to cable, surface connections, bar to vertical ground rod, and many more. Resulting homogeneous bond guarantees longer life. They do not deteriorate or damages with time. An all-purpose graphite mold is designed according to the type of joint to be made and also considering the material of the conductor.

Joints formed:

• Tee joint

• Full Cross joint

• Half Cross joint

• Parallel connection

• Straight joint

• L joint, etc.

Procedure

Before beginning the process – you must be well aware about all the safety measures. You would require an exothermic welding jointing kits which involves – Graphite mould, welding power, handle clamp, flint gun, mould brush, clamp brush, mould scraper and file card brush. Firstly, clean the surface of mould and the conductors. Then position the conductors inside the mould. Before closing the mould - pour weld powder which consist of welding powder and starting powder. Close the lid. Then using a handle clamp hold the conductors locked inside mould. Ignite the powder using flint gun. Heating of the powder creates a chemical reaction. Finally, after this chemical reaction a mechanically strong link is formed.

Features

• Advanced method ensuring high electrical conductivity.

• Non-porous bond formation.

• Non-corrosive and also withstand extreme temperature.

• Does not get impaired with time.

• Enhances the earthing installation.

• Compliance - IEEE 837, UL 467, National Building Code 2016.

Your choice of an appropriate conductor and enhancement compound will be ineffective until and unless you connect and secure them well with a suitable welding system.

What is exothermic welding process?

This is an important stage in earthing installation which is used to join two conductors and to make electrical connections. It is a crucial process which determines the continues flow of current which does not require any external heating provision. This is done to link bar to bar, bar to cable, cable to cable, surface connections, bar to vertical ground rod, and many more. Resulting homogeneous bond guarantees longer life. They do not deteriorate or damages with time. An all-purpose graphite mold is designed according to the type of joint to be made and also considering the material of the conductor.

Joints formed:

• Tee joint

• Full Cross joint

• Half Cross joint

• Parallel connection

• Straight joint

• L joint, etc.

Procedure

Before beginning the process – you must be well aware about all the safety measures. You would require an exothermic welding jointing kits which involves – Graphite mould, welding power, handle clamp, flint gun, mould brush, clamp brush, mould scraper and file card brush. Firstly, clean the surface of mould and the conductors. Then position the conductors inside the mould. Before closing the mould - pour weld powder which consist of welding powder and starting powder. Close the lid. Then using a handle clamp hold the conductors locked inside mould. Ignite the powder using flint gun. Heating of the powder creates a chemical reaction. Finally, after this chemical reaction a mechanically strong link is formed.

Features

• Advanced method ensuring high electrical conductivity.

• Non-porous bond formation.

• Non-corrosive and also withstand extreme temperature.

• Does not get impaired with time.

• Enhances the earthing installation.

• Compliance - IEEE 837, UL 467, National Building Code 2016.

Your choice of an appropriate conductor and enhancement compound will be ineffective until and unless you connect and secure them well with a suitable welding system.

Comments

Post a Comment